News and events

“HWS was invited by VATTENFALL to Amsterdam Headquarters, thanks to the EU EIC event”

May 24th, Amsterdam, The Netherlands.

May 24th, Amsterdam, The Netherlands.

Mariano Abadia and Erik van der Woude presenting the work of HWS Concrete Towers (www.hwstowers.com) to VATTENFALL (https://lnkd.in/dCEYGiHK), at the event organized by the EU-EIC (https://lnkd.in/d5Z382N6).

• One week ago we had the opportunity to introduce the products that the HWS’ team has been developing in the world of precast/prestressed concrete structures for over ∼45 years.

• Specifically the bridges made of MODULAR parts joined by the simple and efficient AirJOINT/BSST (∑ Parts + Joints = “LEGO concept”), solutions in which we see high applicability to future offshore wind energy installations.

• It was a pleasure to show this work to a very interested and highly qualified team.

More information and examples about this type of innovative (but not recent) bridge solutions:

(1994) https://lnkd.in/dzH29cAv

(2011) https://lnkd.in/dy8b2DYN

(2012) https://lnkd.in/d-8SAzDU

(2014) https://lnkd.in/dr-M_zDz

(2011) https://lnkd.in/dvFf-HaQ

“HWS will attend WindEnergy 2023 (Booth C2-A10), in Copenhagen DK, April 25th to 27 th” (HWS)

Looking forward to seeing you all at WindEnergy 2023, in Copenhagen DK, April 25th to 27 th!

Please feel free tu visit us on the HALL C2 – BOOTH A10, as part of the “Wind Energy Basque Country” group.

If you want to know a bit more about AirCLIMBER self-climbing crane, precast/prestressed concrete AirTOWERs up to 220 m Hub Height, the AirBASE precast foundations and other HWS CONCRETE TOWERS’ projects in which we are working on all over the world, please do not hesitate in contacting directly to arrange a meeting:

José-Manuel Sorazu, jmsorazu@hwstowers.com

Mariano Abadía, mabadia@hwstowers.com

We will be glad to assist you.

“Rock anchors are a very good and reliable solution, but….” (HWS)

Rock anchors—with cables or bar tendons—are a very good and reliable solution, but it is important to note that they have maintenance.

If not it can become like this case, built ∼10 years ago.

“HWS introduces two new AirTOWER innovative concepts, for WTG” (HWS)

With this we are authors of up to 4 versions and innovative concepts:

➜ v1 GAMESA G10 (2.005): HWS developed in 2.005 its first hybrid tower hired by GAMESA, for then innovative G10’ turbine: 120 m Huh Height (HH), divided in a 80 m of concrete and 40 m of steel.

➜ v2: A simplification of the above is todays’ most commonly used structural-scheme for an hybrid tower, which can reach 140 m HH in full-concrete or 165 m HH in its hybrid version.

Currently HWS continues to work on innovative concepts, introducing recently two new versions:

➜ v3 “aitstar” by IngZero (www.ingzero.com): Looking for the most cost-effective hybrid tower, with a reasonable height of 110 to 130 m HH. It includes simplifying and lowering the cost not only of the parts manufacturing, but also of simpler transport and easier assembly and construction in the field.

➜ v4 “SuperTALL”: Focused on to reach the maximum height —220 m HH or more…— with a full-concrete or hybrid tower. In addition to new structural concepts it requires a special crane, which has also been developed by HWS: the AirCRANE (https://lnkd.in/dhkgFntN).

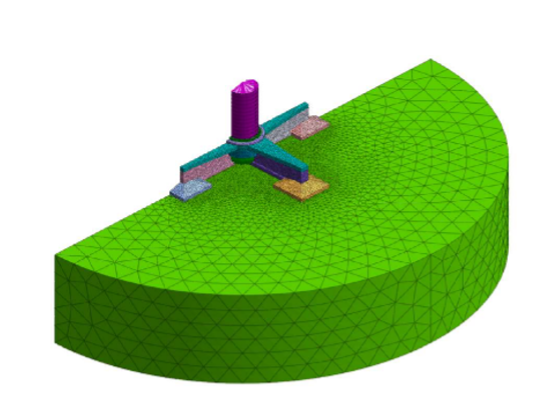

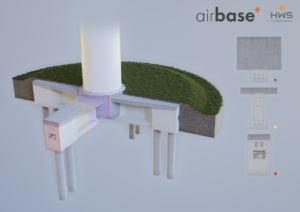

“New version of the AirBASE: Deep foundation, therefore with PILES but not PILE-CAPS” (HWS)

Today we introduce our last development:

An alternative for AirBASE as a deep foundation with PILES but NO PILE-CAPS.

Obviously the reduction of materials, cost and CO2 emission is huge, while the structural performance is optimal.

• If you are looking for a TRUE INNOVATION, ….please think in HWS-AirBASE—a precast foundation for Wind Turbines:

• It is the only true innovation in the field—since the P&H concept (USA, 1994)—because it is also a completely new structural scheme, which introduces multiple advantages: https://lnkd.in/dXfZs5sr

Looking forward to seeing you all at Wind Energy 2023 in Copenhagen DK, April 25th.

Please feel free tu visit us on the HALL C2 – BOOTH A10, as part of the “Wind Energy Basque Country” group.

Fair details: https://lnkd.in/d752QGfi, https://lnkd.in/d4Ye7ERS

HWS’ products details: https://lnkd.in/e8fjmFyC, https://lnkd.in/e8vnF_V5

“The HWS-AirBASE—a precast foundation for Wind Turbines: an TRUE INNOVATION in the wind Energy Sector” (HWS)

If you are looking for a TRUE INNOVATION, ….please think in HWS-AirBASE — a precast foundation for Wind Turbines:

It is the only true innovation in the field—since the P&H concept (USA, 1994)—because it is also a completely new structural scheme, which introduces multiple advantages:

- Up to 35% COST reduction, depending on the WTG-Model (hub height, tower material, rotor diameter and power rated, which means more weight on top of the tower) and SOIL characteristics.

- Up to 50% MATERIALS reduction (steel and concrete), while avoiding technical issues and long working time associated to assembly up to 100-150 t of rebar and pouring 700-1.000 m3 of concrete.

- Up to 50% CO2 EMISSIONS reduction, which is directly the amount of materials reduction, since transport and labour represent less than 10% of those emissions.

Several structural and geotechnical advantages:

- The load transfer to the soil is much more efficient: in fact it is regular, improving any “gapping” issues.

- Being a cross of bridge-girders, with only a small increase of length you will be able to resist much more momentum, which is the main load the Wind Turbine introduces, and must be resisted and transferred by the foundation.

- Higher Stiffness, which is becoming an issue in the new WTG’ designs.

Being partially a precast parts, all advantages of precasting are obviously introduced:

- Use of more resistant concretes.

- Better quality control.

- Better timetable/schedule control.

- Possibility of longer lasting working time on the field in strong/rough weathers, both cold and hot.

- Processes industrialization.

- Serialization of the design foundation: it is possible to develop a catalogue of foundations for a particular WTG.

If you would like to know more about our project, we will be delighted to welcome you in our booth in n the WindEnergy Hamburg-DE fair, next September 27-30, Hall B2, booth B2.EG.410A.

Kindly reserve your time slot so we will able to attend you better. Please do it writing to jmsorazu@hwstowers.com

“CENER met the self-climbing AirCRANE demonstrator, March 18th” (HWS)

ENG:On 18 March, Mr. Pablo Ayesa, General Director, and Mr. Antonio Ugarte, Director of the Wind Energy Department, both members of the CENER (Spain´s National Renewable Energy Centre, https://www.cener.com/en/) met, at the workshops of the company KEYTECH (www.keytech.es) located in Lecumberri (Navarre), the demonstrator of the self-climbing AirCRANE, development granted by the European Commission, under “Horizon 2020-SME Instrument”, No 804858 (Link to CORDIS: https://cordis.europa.eu/project/id/804858).

Also in attendance were Mr. Juanjo Etxalar and Mr. Telmo Sexmilo, representatives of CLAVE (https:/clave.capital) of Pamplona (Navarre), which manages the participation of the Basque industrial conglomerate MONDRAGON CORPORATION (https:/www.mondragon-corporation.com) in HWS, and that they will shortly expand its participation in HWS, together with INNVIERTE (https://www.cdti.es), to start the worldwide marketing of the developed solution.In this way HWS Concrete Towers S.L. strengthens and guarantees its future.”_______________________________________

ES: “El pasado 18 de Marzo, D. Pablo Ayesa, Director General, y D. Antonio Ugarte, Dtor. Departamento de Energía eólica, ambos de CENER (Centro Nacional de Energías Renovables, https://www.cener.com) conocieron en los talleres de la empresa KEYTECH (www.keytech.es) localizados en Lecumberri (Navarra) el demostrador de la grúa auto-trepante AirCRANE, desarrollado con ayuda de la Comisión Europea, Programa “Horizon 2020-SME Instrument”, nº 804858 (Link a CORDIS: https://cordis.europa.eu/project/id/804858).También asistieron D. Juanjo Etxalar y D. Telmo Sexmilo, representantes de CLAVE (https://clave.capital) de Pamplona (Navarra), quienes gestionan la participación del conglomerado industrial vasco CORPORACION MONDRAGON (https://www.mondragon-corporation.com) en HWS, y que van a ampliar en breve su participación en HWS, junto con INNVIERTE (https://www.cdti.es), para iniciar la comercialización mundial de la solución desarrollada.De esta forma HWS Concrete Towers S.L. refuerza y garantiza su futuro.

“How much does the Wind Energy learn from Wind Sailing (…and viceversa) ?” (HWS)

As along last decade, completely new wind boats like Americans Cup AC75 monohull vessels (*) are appearing, completely new concepts with an exceptional efficiency which allows to fly over the sea near to 100 Km/h, or even surpassing (∼104 Km) with a Windsurf (**).

(*) The newest American’s Cup AC75 are 75 feet (22.86m) keel-less yachts, which rise out of the water on hydrofoils and glide across the surface to reach speeds in excess of 50 knots (93 Km/h).

The Challenger yacht “Luna Rossa” had maxed out at 53,4 knots (99 Km/h), (…) and Team New Zealand’s “Te Rehutai” is rumoured to be even faster.

- Source: https://edition.cnn.com/2021/03/09/sport/americas-cup-yachts-speeds-sailing-spt-intl/index.html

(**) On Thursday, November 18, 2021, in Namibia, Mr. Bjorn Dunkerbeck (the famous Dutch & Canarian 52-year-old famous windsurfer) broke that speed barrier, hitting 103,67 Km/h over a two-second time gap, and holding an average speed of 101,00 Km/h kilometers per hour over a 100-meter stretch of water.

- Source: https://www.surfertoday.com/windsurfing/bjorn-dunkerbeck-hits-windsurf-top-speed-of-103-67-kmh

- YouTube video, showing windsurf “flying” at near 104 Km/h: https://www.youtube.com/watch?v=jt3DQNUJXkc

- YouTube video: Topspeed of 102,35 km/h at Luderitzspeedchallenge 2021: https://www.youtube.com/watch?v=8XcRpbVb_gk