Sustainability

ACHIEVING MORE,

USING LESS and GREENER

Let’s build…

LOCAL

GREENER

REDUCING

REUSING

Wind Energy power is essential to fighting climate change. Wind is set to become the key pillar of the global renewable supply and the strongest force to ensure global decarbonization.

However, building the turbines is energy intensive. It could take between 3 to 11 months to generate the amount of energy that was needed for their construction.

Through HWS’ innovative ideas, wind farm construction becomes ECO-FRIENDLIER, reducing up to 65% of CO2 emissions.

Achieves greater heights (>220 m) , increasing generated energy by 30%

Local Content:

reduces logistics

Material volume reduction

Less Maintenance & Double Lifespan

(>50 years)

65% less CO2 emissions per constructed tower

*Study performed for construction of 5.x MW HH165 m wind turbine tower.

1/7 of the transportation required

Civil work reduction: -75% of crane pads & narrow access roads

80% less material (steel) required during crane manufacturing

Electric powered crane

35% less CO2 EMISSIONS during Installation of Wind Turbines

AirCRANE enables to build bigger turbines at greater heights, pushing forward onshore wind turbine installation technology and helping to decarbonize our planet.

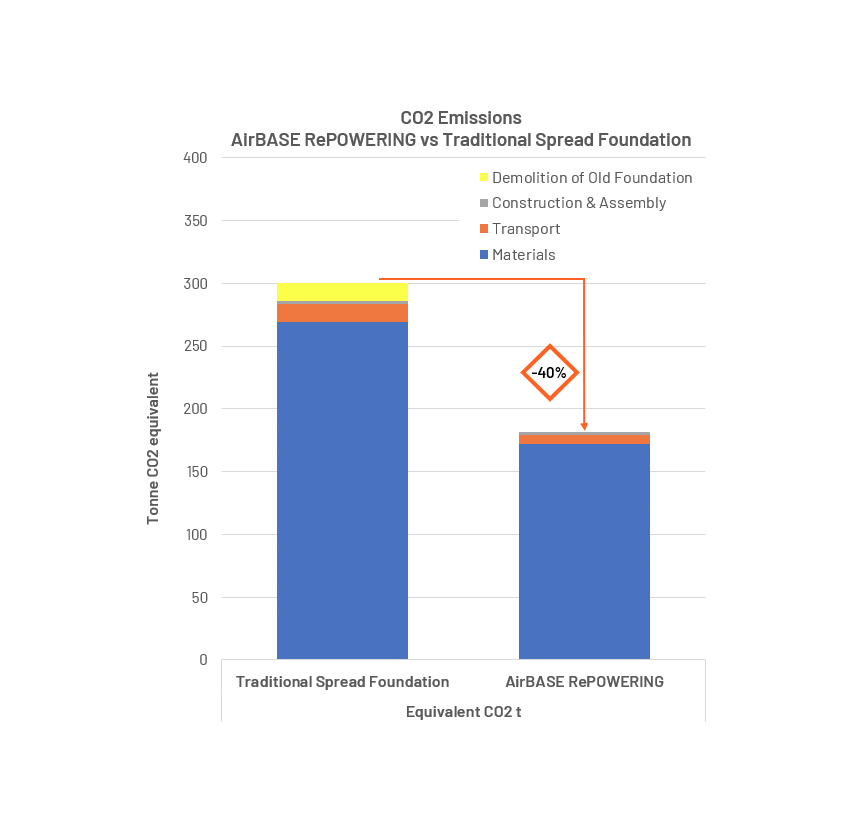

Performed carbon footprint study shows that over 95% of CO2 emissions in construction of wind foundations come from the required materials (concrete & steel). Hence, achieved percentage of material saving reduction will be directly related and similar to the obtained C02 emissions cut.

Up to 45%

of

material savings

Up to 80% less excavation

Double lifespan

Easy dismantling

30% less CO2 emissions per constructed wind foundation

*Study performed for 5.x MW HH150 m wind turbine.

+50% material savings

Reuses existing infrastructure

Avoids demolition of old foundation

Avoids use of new soil

40% less CO2 EMISSIONS per constructed wind foundation in RePOWERING projects

*Study performed for 5.x MW HH150 m new wind turbine, replacing a 2MW old one.