News

“HWS was invited by VATTENFALL to Amsterdam Headquarters, thanks to the EU EIC event”

May 24th, Amsterdam, The Netherlands.

May 24th, Amsterdam, The Netherlands.

Mariano Abadia and Erik van der Woude presenting the work of HWS Concrete Towers (www.hwstowers.com) to VATTENFALL (https://lnkd.in/dCEYGiHK), at the event organized by the EU-EIC (https://lnkd.in/d5Z382N6).

• One week ago we had the opportunity to introduce the products that the HWS’ team has been developing in the world of precast/prestressed concrete structures for over ∼45 years.

• Specifically the bridges made of MODULAR parts joined by the simple and efficient AirJOINT/BSST (∑ Parts + Joints = “LEGO concept”), solutions in which we see high applicability to future offshore wind energy installations.

• It was a pleasure to show this work to a very interested and highly qualified team.

More information and examples about this type of innovative (but not recent) bridge solutions:

(1994) https://lnkd.in/dzH29cAv

(2011) https://lnkd.in/dy8b2DYN

(2012) https://lnkd.in/d-8SAzDU

(2014) https://lnkd.in/dr-M_zDz

(2011) https://lnkd.in/dvFf-HaQ

“HWS will attend WindEnergy 2023 (Booth C2-A10), in Copenhagen DK, April 25th to 27 th” (HWS)

Looking forward to seeing you all at WindEnergy 2023, in Copenhagen DK, April 25th to 27 th!

Please feel free tu visit us on the HALL C2 – BOOTH A10, as part of the “Wind Energy Basque Country” group.

If you want to know a bit more about AirCLIMBER self-climbing crane, precast/prestressed concrete AirTOWERs up to 220 m Hub Height, the AirBASE precast foundations and other HWS CONCRETE TOWERS’ projects in which we are working on all over the world, please do not hesitate in contacting directly to arrange a meeting:

José-Manuel Sorazu, jmsorazu@hwstowers.com

Mariano Abadía, mabadia@hwstowers.com

We will be glad to assist you.

“Rock anchors are a very good and reliable solution, but….” (HWS)

Rock anchors—with cables or bar tendons—are a very good and reliable solution, but it is important to note that they have maintenance.

If not it can become like this case, built ∼10 years ago.

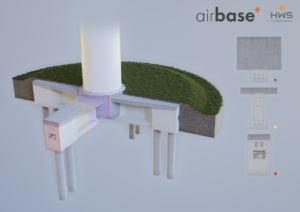

“New version of the AirBASE: Deep foundation, therefore with PILES but not PILE-CAPS” (HWS)

Today we introduce our last development:

An alternative for AirBASE as a deep foundation with PILES but NO PILE-CAPS.

Obviously the reduction of materials, cost and CO2 emission is huge, while the structural performance is optimal.

• If you are looking for a TRUE INNOVATION, ….please think in HWS-AirBASE—a precast foundation for Wind Turbines:

• It is the only true innovation in the field—since the P&H concept (USA, 1994)—because it is also a completely new structural scheme, which introduces multiple advantages: https://lnkd.in/dXfZs5sr

Looking forward to seeing you all at Wind Energy 2023 in Copenhagen DK, April 25th.

Please feel free tu visit us on the HALL C2 – BOOTH A10, as part of the “Wind Energy Basque Country” group.

Fair details: https://lnkd.in/d752QGfi, https://lnkd.in/d4Ye7ERS

HWS’ products details: https://lnkd.in/e8fjmFyC, https://lnkd.in/e8vnF_V5

“The HWS-AirBASE—a precast foundation for Wind Turbines: an TRUE INNOVATION in the wind Energy Sector” (HWS)

If you are looking for a TRUE INNOVATION, ….please think in HWS-AirBASE — a precast foundation for Wind Turbines:

It is the only true innovation in the field—since the P&H concept (USA, 1994)—because it is also a completely new structural scheme, which introduces multiple advantages:

- Up to 35% COST reduction, depending on the WTG-Model (hub height, tower material, rotor diameter and power rated, which means more weight on top of the tower) and SOIL characteristics.

- Up to 50% MATERIALS reduction (steel and concrete), while avoiding technical issues and long working time associated to assembly up to 100-150 t of rebar and pouring 700-1.000 m3 of concrete.

- Up to 50% CO2 EMISSIONS reduction, which is directly the amount of materials reduction, since transport and labour represent less than 10% of those emissions.

Several structural and geotechnical advantages:

- The load transfer to the soil is much more efficient: in fact it is regular, improving any “gapping” issues.

- Being a cross of bridge-girders, with only a small increase of length you will be able to resist much more momentum, which is the main load the Wind Turbine introduces, and must be resisted and transferred by the foundation.

- Higher Stiffness, which is becoming an issue in the new WTG’ designs.

Being partially a precast parts, all advantages of precasting are obviously introduced:

- Use of more resistant concretes.

- Better quality control.

- Better timetable/schedule control.

- Possibility of longer lasting working time on the field in strong/rough weathers, both cold and hot.

- Processes industrialization.

- Serialization of the design foundation: it is possible to develop a catalogue of foundations for a particular WTG.

If you would like to know more about our project, we will be delighted to welcome you in our booth in n the WindEnergy Hamburg-DE fair, next September 27-30, Hall B2, booth B2.EG.410A.

Kindly reserve your time slot so we will able to attend you better. Please do it writing to jmsorazu@hwstowers.com

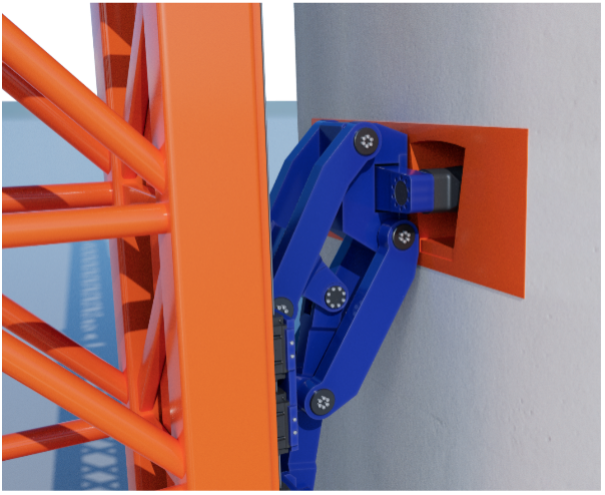

“HWS has developed an universal Concrete-tower ANCHORAGE-System Concept, for installation of wind turbines using self-climbing cranes”

This disruptive anchoring system, enables to all the brand new self-erecting cranes to climb any of the existing concrete towers in the market.

A. Description of the anchorage system

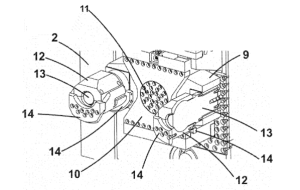

The patented anchorage consists of:

(1) In the CONCRETE TOWER: Some CAVITIES (or HOLES) with a special shape that are left in the tower wall and are protected by some METAL FRAME (inserted on the concrete, orange in the picture). These inserts are economic and easy to attach to the mold and embed during manufacturing of the prefabricated tower segments, without practically altering and making the tower more expensive. The openings in the wall can be through or non-through and take the form of a hole or niche.

(2) In the CRANE: Special metal ‘SPIKES’ (in green in the picture) that get correctly locked in the metal inserts in order to anchor the self-climbing crane to the tower. These SPIKES are barrel-shaped steel elements with rotary motion and some end plates located at the front and rear ends of the piece.

In a hooking position the SPIKES are inserted into some of the tower CAVITIES, in such a way that the lower part of the spike is in contact with the inside of the hollow body of its corresponding metal insert, transmitting the weight of the self-climbing structure to the tower, and being held in position by that weight.

Meanwhile, the end plates are engaged against the peripheral end surfaces of the metal inserts, blocking the horizontal displacement (f.i. caused by wind loading), and therefore avoiding that can be released.

Both the metal inserts and the interlocking spikes can be distributed one by one or in groups, although in pairs is preferred.

B. Advantages of the invention

The special shape of the presented anchorage system provides several advantages:

➜ During INSERTION of the spikes:Its special shape allows for a smooth and guided insertion of the spike into the cavity. In addition, the rotary motion assigned to the spikes promotes self-correction of possible position and alignment errors in the hitch. This way, the location of the anchoring elements in the concrete modules does not require of high precision.

➜ During OPERATION and CLIMBING of the crane: The anchorage completely relies on gravity, avoiding any mechanical locking device that could get blocked at height due to some dirt, material expansion, or deformation. Moreover, the round shape of the spike leads to optimum (homogeneous and centered) load distribution of the climbing device to the concrete tower. In such manner, larger loads can be withstood in all directions, resulting in higher performance of the self-climbing crane by increasing its lifting capacity and operational wind speed.

➜ During EXTRACTION of the spikes:It follows the same smooth and guided process as during the insertion. Furthermore, since no mechanical locking device is included, the system cannot get jammed at heights where reparation is time consuming and expensive.

Hence, it is concluded that the design of the presented anchorage system favours the insertion, correct support, and extraction of the spikes, leading to a safe, reliable, maintenance and reparation-free system.

C. Performed studies

The behaviour of the anchorage system has been analyzed through advanced finite element models for different concrete tower types:

- With varying wall WIDTH: From 15 to 35 cm.

- With different tower segment LENGHT: From 3.6 to 20 m.

- With diverse tower segment WEIGHT: From (30 t) 60 to 265 t.

The anchorage has shown excellent response in all the studied scenarios, only requiring of some additional REBAR reinforcement around the anchorage area in certain cases.

The analyses have also shown that some plastification of the bottom part of the METAL FRAME (or inserts) embedded in the tower wall occurs during maximum loading conditions. This has been designed this way to optimize the anchorage.

The metal inserts are made of a lower resistance steel than the spikes so that plastification of the spikes is always avoided. The spikes are part of the self-climbing crane and will be constantly used for assembly of different towers and wind turbines. Hence, the perfect condition of these pieces must be ensured along the lifetime of the crane. However, the metal inserts are barely going to be used along the lifetime of the tower, only during construction or maintenance works. Thanks to the special shape of the system, allowing some plastification of the inserts in a localized area, does not compromise the correct subsequent functioning of the anchorage or blockage of the system.

This leads to an optimum design of the system while guaranteeing the perfect condition of the spikes and ensuring the correct operation of the system.

D. Other developments

- For already built concrete towers, where the metal inserts cannot be embedded during manufacturing, HWS has developed an anchoring version, in which a plate that can be easily bolted externally to the tower is proposed. This way, maintenance of existing towers through self-climbing crane technology is enabled.

- On the other hand, HWS is currently developing a different anchorage system for enabling self-climbing cranes to install steel towers. In this case, the anchorage points will be attached to a reinforced flange placed between the steel tower segments. This flange will have four connection points at the same horizontal plane: the two outer ones will be used by one climbing device and the two internal ones by another one.

Further information cannot be disclosed since it is currently under development and susceptible to patent.

E. Conclusion

- In conclusion, HWS presents this development as a unique anchoring system applicable to any concrete tower and adaptable to any self-climbing device.

- This invention could be envisaged as the standard anchorage system to push and establish the use of self-climbing cranes in the construction of wind turbines.